Increases in electricity prices are affecting not only households but also industrial facilities. For industrial plants, which consume high amounts of energy in their production processes, these increases translate into cost pressures that negatively impact competitiveness. At this point, improving energy efficiency is critical for both environmental and economic sustainability.

Fluid systems used in industrial facilities can lead to hidden energy losses if they are poorly designed or rely on outdated technology. However, with next-generation pump technologies and engineering solutions based on system analyses, energy savings of 20% to 40% can be achieved. This provides an effective way to mitigate the impact of rising electricity costs.

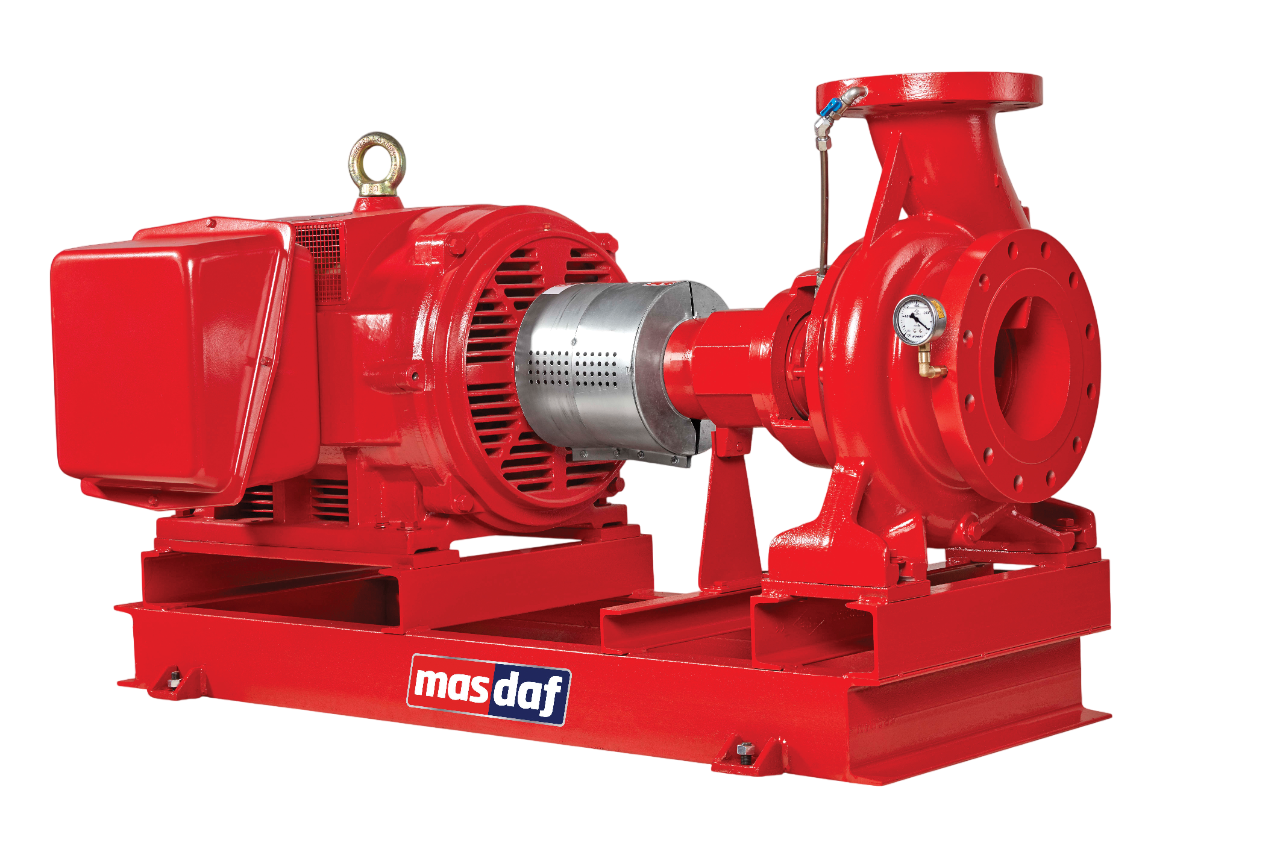

Commenting on the topic, Erhan Özdemir, General Manager of Masdaf, Turkey’s leading fluid technologies company, said:

“Approximately 20% of the world’s electricity consumption is spent on pump systems. Especially when considering the life-cycle costs of pumps operating more than 2,000 hours annually, it is clear that a large portion of these costs comes from electricity consumption. When analyzing total lifetime costs, the initial investment in pumps accounts for only about 5% to 8%, while the remaining majority is energy cost. Therefore, industrial facilities particularly need efficient pump systems. Rising energy costs directly affect production costs and competitiveness of industrial enterprises. For this reason, industrial companies need to use energy-efficient fluid technology products to reduce energy expenses. At Masdaf, we not only manufacture fluid technology solutions but also guide industrial facilities on their sustainability journey with energy-efficient system solutions.”